Terafood

Compact and affordable sensor for monitoring food quality

Why this project?

We have all been there: you have an unopened package of fresh fish in the refrigerator that is (almost) just past its best-by date and you wonder if it is safe to eat. What do you do?

You open the package and smell it. While this might be a good solution at home, this will not work for food companies, distribution centres or hops because opening individual packages negates the protective packaging atmosphere. The absence of a non-destructive individual testing method causes enormous amounts of food waste. It is estimated that retail and consumers are responsible for more than 40% of the annual food waste in developed countries (Source: FAO, 2011).

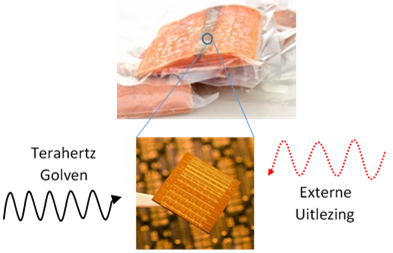

Food products with a limited shelf life, such as fresh fish, go bad because of microbial activity which leads to the creation of Volatile Organic Compounds (VOCs). The Terafood project researches the development of a sensor that can detect early food decay inside individual packages based on VOCs, avoiding the need to open or damage the packaging. This sensor uses terahertz technology. Integrating this sensor in food packaging will allow real-time quality monitoring during every phase of storage, without opening the packaging.

Why use terahertz light frequencies? The advantage of terahertz frequencies is that they penetrate most packaging materials while being able to interact with the VOCs inside the packaging, allowing for characterisation of a large part of the VOCs (via the molecular fingerprint). This means that an external monitoring system can be used without opening the package (compatible with a passive sensor inside the package). This also applies to, for example, HDPE, which looks black to us but is transparent to terahertz waves. Terahertz frequencies are non-destructive and harmless to humans.

Real-time quality monitoring of the food inside a package is still somewhat of a pipe dream, but it could lead to a significant reduction in food waste, thus providing both a financial and an ecological breakthrough.

Research approach

TERAFOOD is an interregional research and development project (Interreg Belgium-France) that researches the development of a teraherz technology-based sensor to monitor food decay.

The research consists of 3 separate parts

- Characterising the VOCs linked to food decay

- Developing principles to measure VOCs with terahertz technology

- Developing the physical sensor

Target group and expected results

Real-time, non-destructive quality control mainly benefits food companies, retailers and (large) shops that want to manage their inventory efficiently, but also food packaging manufacturers that will be able to integrate a sensor into their packaging.

This project is the first step in the development of an applicable sensor. The proof of concept is expected to be fine tuned by the end of the project. The next step in bringing the technology to the market will be to make the sensor completely compatible for use in food packaging.

The project has established an industrial advisory committee that includes parties from outside the project to help determine the course of the project. If you are interested in joining this advice committee, please contact Sofie Verdoodt.

Project Partners

The consortium consists of partners for the academic world and the industry with the necessary expertise to develop the technology and the sensor. In addition, the consortium has enlisted partners that are specialised in bridging the gap between the academic world and the industry. These partners will oversee the valorisation and dissemination of the sensor technology.

Academic partners:

- CNRS (IEMN) (coordinator)

- Ghent University

- Department for Food Safety and Food Technology

- Fotonics research group

- Université Litorale de Cote Opale

Industrial partner:

- VMicro

Cluster partners:

- Flanders’ FOOD

- Food2Know